UMD Consulting Services collaborates with multidisciplinary teams to integrate advanced robotic solutions that minimize human intervention in hazardous environments. Our commitment to automation and digital systems reflects a dedication to quality, safety, and innovation. By leveraging cutting-edge technologies, we reduce risk and increase efficiency, positioning UMD as a forward-thinking leader in the Oil & Gas industry. This approach not only enhances operational reliability but also underscores our role as a strategic partner, empowering clients to navigate complex challenges with confidence and precision.

Subsea Interventions

Driving Efficiency and Innovation in Offshore Operations

1. Hydrate Remediation

Project Highlight:

• Resolved hydrate blockages in over 20 projects, including campaigns in the Gulf of Mexico and West Africa.

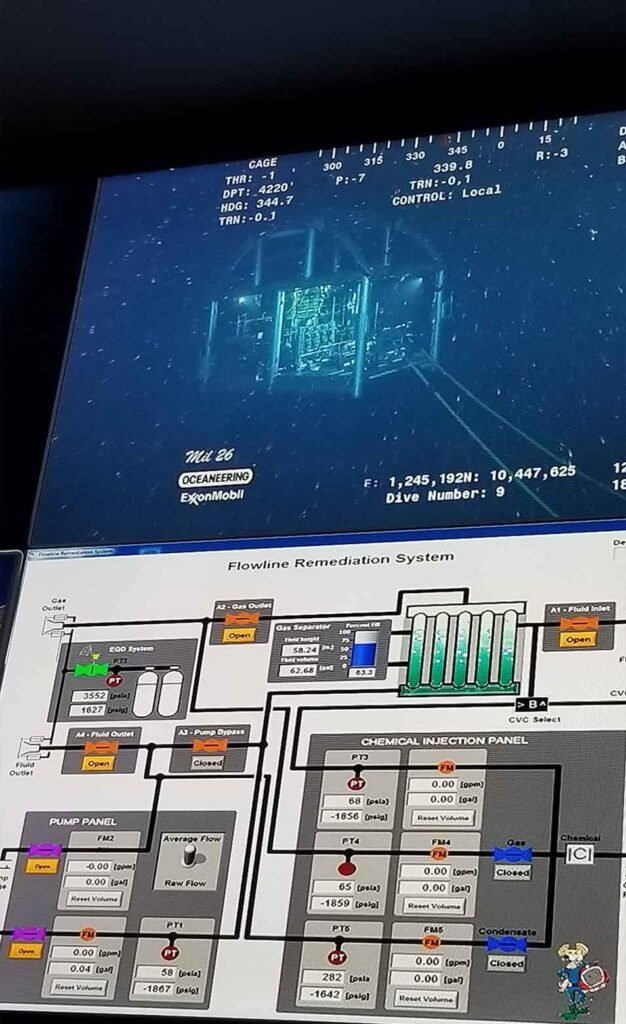

• Utilized cutting-edge ROV-mounted deployable skids and subsea separation systems, including systems capable of methanol injection, heat application, and depressurization up to 15,000 psi.

Solution:

• Advanced techniques, such as precise fluid and volume calculations, pinpointed blockage locations.

• Operations integrated multi-stage systems to inject chemicals like methanol, apply heated fluids, and depressurize subsea equipment.

• Implemented ROV-mounted tools with hot stabs and real-time monitoring to ensure precision in dislodging hydrates.

Outcome:

• Fully restored production flow, reduced downtime, and re-established well functionality. Innovative methods decreased environmental impact by minimizing operational delays.

2. Well Stimulation

Project Highlight:

• Managed and executed the stimulation of over 100 subsea wells since 2012, including 10 deepwater wells in the Gulf of Mexico completed in just 6 months with a 98% operational success rate.

Solution:

• Delivered coiled tubing applications combined with a subsea riserless stimulation tool to pump acids and diverters for enhanced well access and performance.

• Adopted treatment plans tailored to address specific reservoir characteristics and optimize longterm output.

Outcome:

• Significantly increased production rates and improved reservoir performance. Extended asset life while lowering operational costs through efficient stimulation campaigns.

3. Light Well Intervention (LWI)

Project Highlight:

• Conducted over 15 successful interventions using 4” and 7” riserless systems, leveraging MSVdeployable well access packages.

Solution:

• Deployed modular subsea systems featuring shearable and gate valves for secure well control.

• Implemented real-time well monitoring and cutting-edge technologies to ensure compliance with stringent safety standards and equipment reliability.

Outcome:

• Achieved substantial cost reductions by avoiding traditional rig-based operations, significantly minimizing the environmental footprint with lower CO2 emissions and a smaller operational footprint.